In the quest for efficient water management, leakage reduction stands as a critical objective for water utilities worldwide. Leakage not only leads to the wastage of precious water resources but also poses financial and environmental challenges.

To address this issue, hydraulic modelling has emerged as an indispensable tool that bolsters our understanding of water networks and directs our leakage reduction efforts. In this blog post, we will delve into the benefits of hydraulic modelling and highlight how the collaboration between TOBIN and our partners is instrumental in achieving an ambitious leakage rate target of 25% by 2030.

This partnership leverages the power of hydraulic modelling to drive effective leakage reduction strategies. By utilising advanced software and expertise, the collaboration aims to identify high-leakage areas, develop targeted pressure management plans, and optimise infrastructure investments.

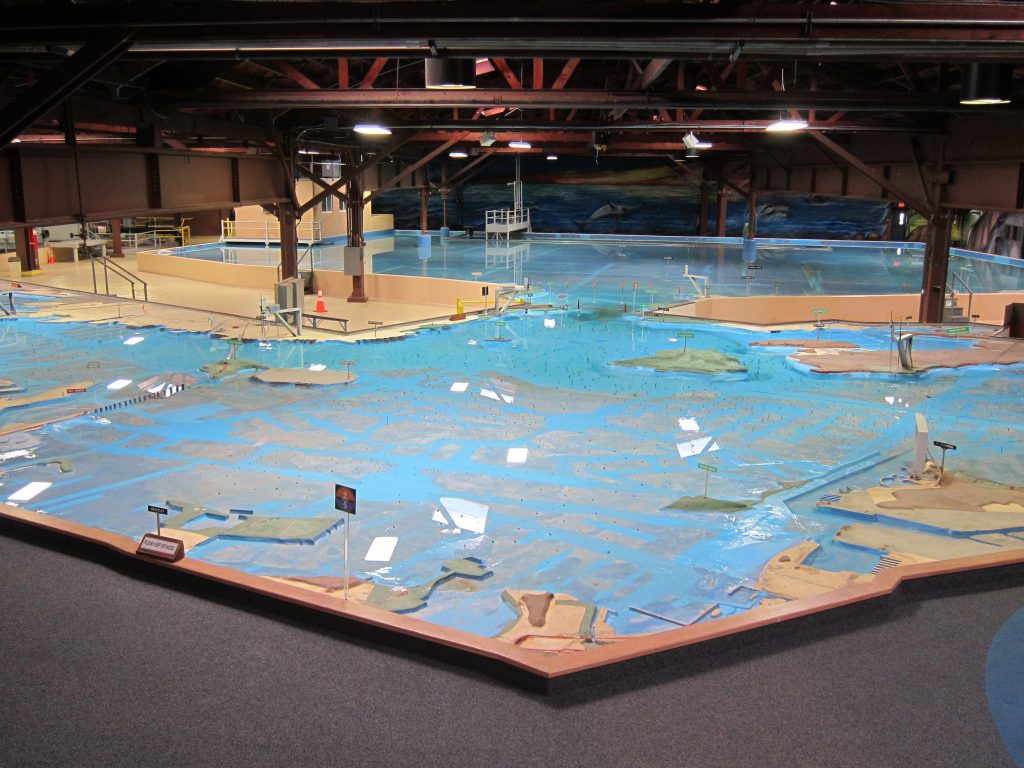

What is Hydraulic Modelling? In the 1950s, the U.S Army Corps of Engineers developed a hydraulic model to explore the idea of damming the San Francisco Bay, and it looked like this! (image on the left). Nowadays, hydraulic modelling is a digital process also used to represent what’s happening in the network that delivers drinking water to our homes on a day-to-day basis.

It involves the use of specialised software to simulate and analyse the behaviour of water flowing through pipes, pumps, valves, and other hydraulic components.

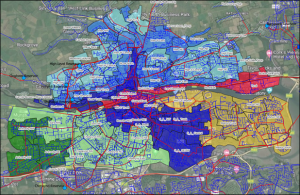

The hydraulic modelling representation of the Cork City network looks like this! (Image on the right).

The modelling process typically involves the following steps:

Model Construction: Gathering information about the water supply network, including pipe sizes, lengths, elevations, locations of pumps and valves, and customer demand data. Then inputting the collected data and configuring the model to accurately reflect the system’s characteristics.

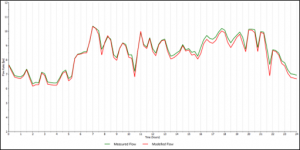

Calibration and Validation:

Adjusting the model parameters to match the observed behaviour of the actual system. This is done by comparing the model’s predictions with field measurements. A high-confidence model allows to predict parameters like flow rates, pressure levels, velocities, and water age ensuring that the model accurately represents the real-world network.

Benefits of Hydraulic Modelling:

Scoping Pressure Management Options: One of the primary advantages of adopting hydraulic modelling to tackle network leakage. By accurately simulating the flow of water through the network, hydraulic models provide insights into the areas experiencing excessive pressure.

These high-pressure zones are often prone to leaks and bursts, making them prime candidates for pressure management interventions.

The hydraulic model can then be used to identify an optimal approach to pressure management, such as installing pressure-reducing valves or rezoning sections, to mitigate leakage risks and improve overall system performance.

The collaboration between TOBIN and our partners stands as a shining example of how this technology is being harnessed to achieve ambitious leakage reduction targets. With such concerted efforts, 24 new pressure management opportunities have been identified so far across 8 Water Supply Zones. The related daily water savings are equivalent to half of the size of an Olympic swimming pool or almost 1,200 cubic metres of water per day!